- Have any questions?

- +353 (0)57 859 3945 or +353 (0)87 796 5622

- info@thermalimagingireland.ie

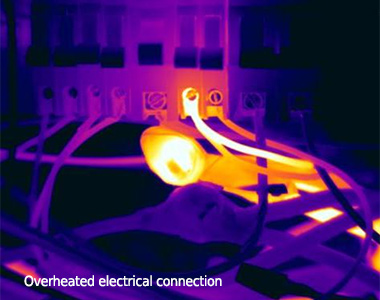

Infrared Electrical Surveys

Infrared Scans of Electrical Power Systems

Saves your business money

Infrared thermography quickly identifies potential problems with electrical circuits before they fail. Regular surveys will reduce unscheduled downtime and avoid catastrophic failure.

Infrared scanning of electrical systems and moving machinery is the most effective strategy for preventive maintenance.

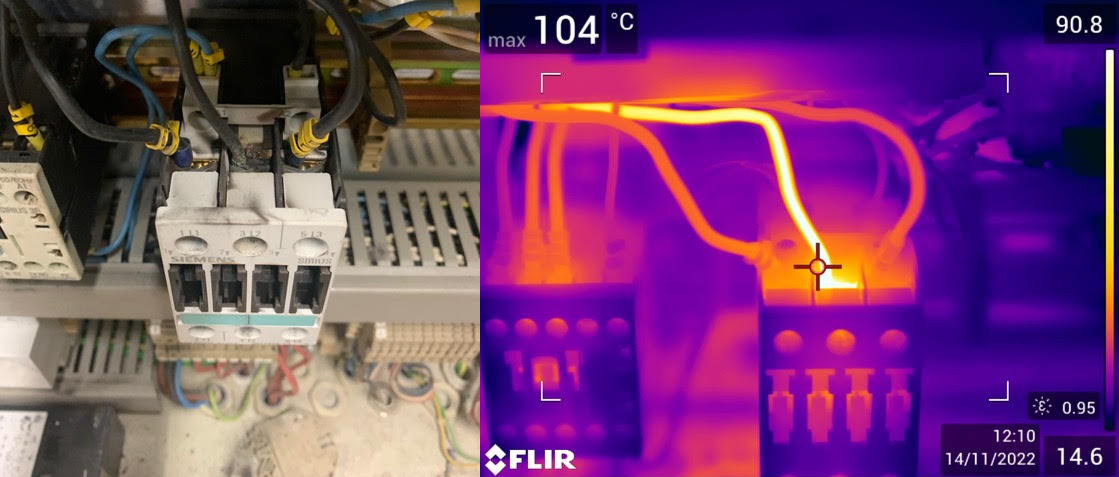

This was a fire waiting to happen...

Found during annual thermographic inspection:

Damaged connection to electrical component, temperature 104C, melted insulation.

This component is part of a control system on an industrial packaging line.

Infrared scanning of Electrical power systems will determine whether components of the systems have been properly installed and are undamaged.

An infrared electrical survey can reduce downtime by eliminating the risk of equipment failure, increasing safety and improving insurability.

An infrared scan can improve system performance by determining whether system components are operating properly and meet the design intent.

A thermal imaging electrical survey will ultimately save money in the installation of systems by determining if components of systems comply with the project specifications and design, reducing construction schedule delays.

If you are moving into a new commercial premises, or are installing, upgrading or maintaining a commercial power system, call us today to organise an electrical infrared survey of the site.

Infrared Thermography will uncover any underlying problems, and early detection will enable maintenance technicians to take corrective action before a component fails, minimizing damage to the component and reducing repair costs.

Contact us today to discuss how an infrared thermographic inspection could save money for your business.