- Have any questions?

- +353 (0)57 859 3945 or +353 (0)87 796 5622

- info@thermalimagingireland.ie

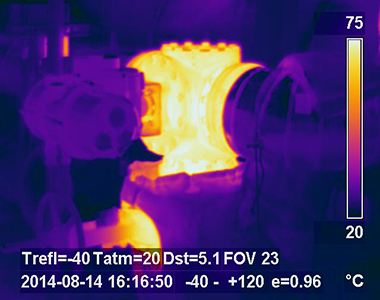

Infrared Thermal Imaging Mechanical Inspections

Infrared Scans of Mechanical Processes

Saves your business money

A Mechanical Thermographic Survey will identify damaged or failing components which can then be changed in time to avoid costly breakage or interruption to mechanical processes.

Thermal imaging inspections of mechanical processes take less time and money than repairs, and can be a valuable tool in a manufacturing company's predictive maintenance strategy.

Mechanical inspections may require comparing similar pieces of equipment; two identical motors operating under the same conditions should yield similar infrared images.

Any possible future failure may be evident by comparing the Infrared images. Early detection of a possible component failure allows for scheduled repairs and avoids expensive downtime.

Using an Infrared camera with direct temperature readout, a thermographer can show a technician instant temperature results which will indicate whether components are operating under stress.

Infrared thermography surveys are essential tools for an efficient predictive maintenance programme, as the infrared camera can quickly measure and compare heat signatures for each piece of equipment, without disrupting operations.